Liquide de démoulage concentré pour empêcher la cire d'adhérer aux rouleaux des machines à gaufrer. Il est servi en bouteilles de 5 litres.

Anyone who's ever run wax through a laminator without release agent knows exactly what I'm talking about: the sheet comes out uneven, sticks to the roller, tears... and you end up scraping residue with a spatula while quietly cursing. Wax laminating seems straightforward until something goes wrong, and adhesion is the most common and frustrating problem.

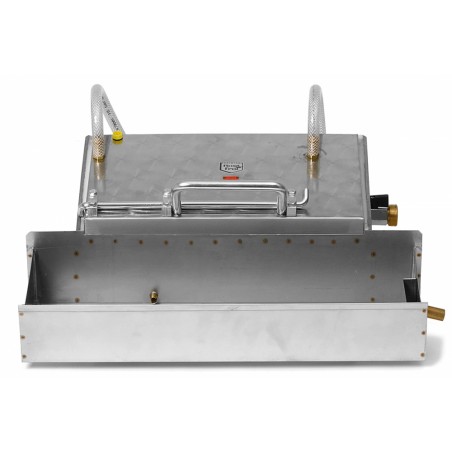

This concentrated release agent is the official formula used in German RIETSCHE laminators, a benchmark in the industry for their finishing precision. Its function is simple but critical: it creates a microscopic film between the molten wax and the roller surface, allowing clean and consistent release. The result is uniform sheets with well-defined cell pattern and none of those typical drag marks.

It works by dilution in the cooling circuit —that cold water circulating inside the rollers that solidifies the wax on contact—. With just 20-30 ml per 10 litres of water you achieve optimal performance, making this 5-litre container a reserve for many working sessions.

Although formulated for RIETSCHE, it's perfectly compatible with any cooled-roller laminator: Lyson, Logar, or handmade models. If you produce your own foundation sheets —whether for personal use or sale—, this small detail makes the difference between professional laminating and one that causes problems.

Presentation: 5-litre container, concentrated.

Liquide de démoulage concentré pour empêcher la cire d'adhérer aux rouleaux des machines à gaufrer. Il est servi en bouteilles de 5 litres.

check_circle

check_circle