Automatic uncapping machine with heated knives and electric feeder for Langstroth or Dadant frames. Designed for high-throughput professional honey houses.

When you arrive at the honey room after a good harvest and see the stack of supers waiting their turn, you know the real work is about to begin. Manual uncapping, which is manageable with 20 hives, becomes a bottleneck when processing 50-60 frames per batch. That’s where an automatic uncapping machine with feeder changes the game: efficiency, safety, and reduced physical effort.

This PREMIUM line model, made entirely of stainless steel, automates the process with a continuous feed system and adjustable heated knives, ensuring uniform uncapping without damaging the comb cells. All controlled from a central digital panel.

Two versions available depending on your frame type:

• For Langstroth and Dadant US frames (medium and deep)

• For Dadant Blatt frames (European standard sizes)

What problem does it solve?

Manual uncapping is not only slow but also introduces variability and risks: cold knives, uneven cappings, risk of cuts... This machine automates the process, ensuring consistent and clean results while optimizing your workflow.

How it works:

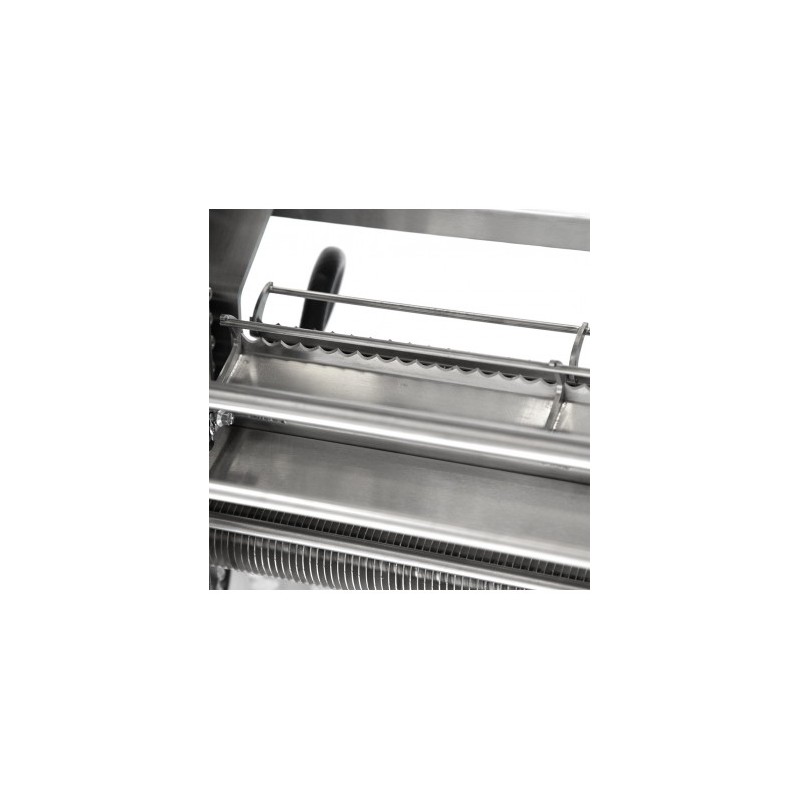

• Automatic feeder: loads frames one by one with adjustable speed from the control panel.

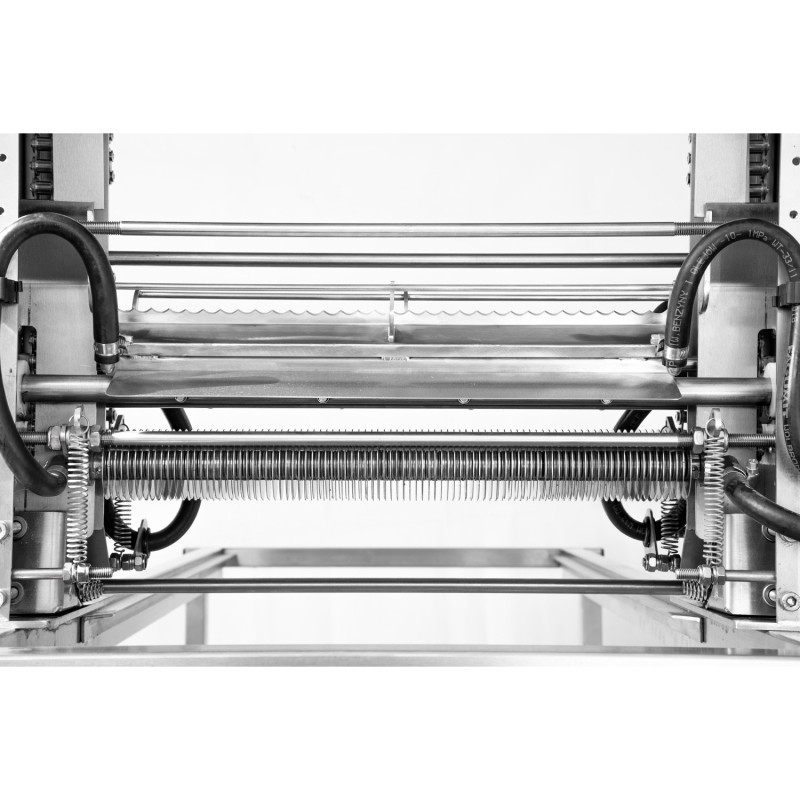

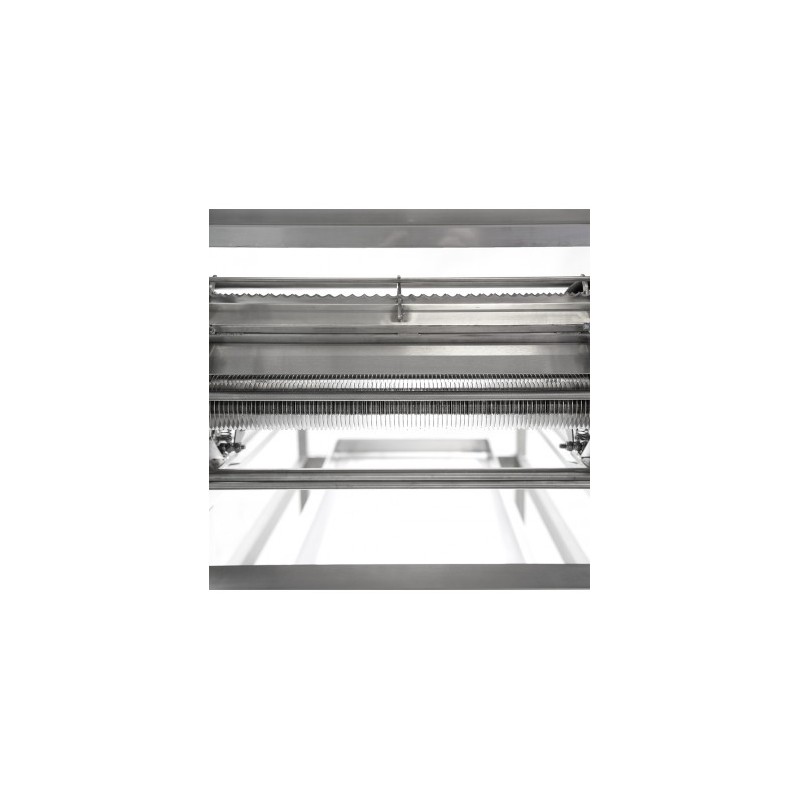

• Heated knives: remove cappings at the exact temperature you set, adaptable to wax hardness (ideal for crystallized honeys like thyme or heather).

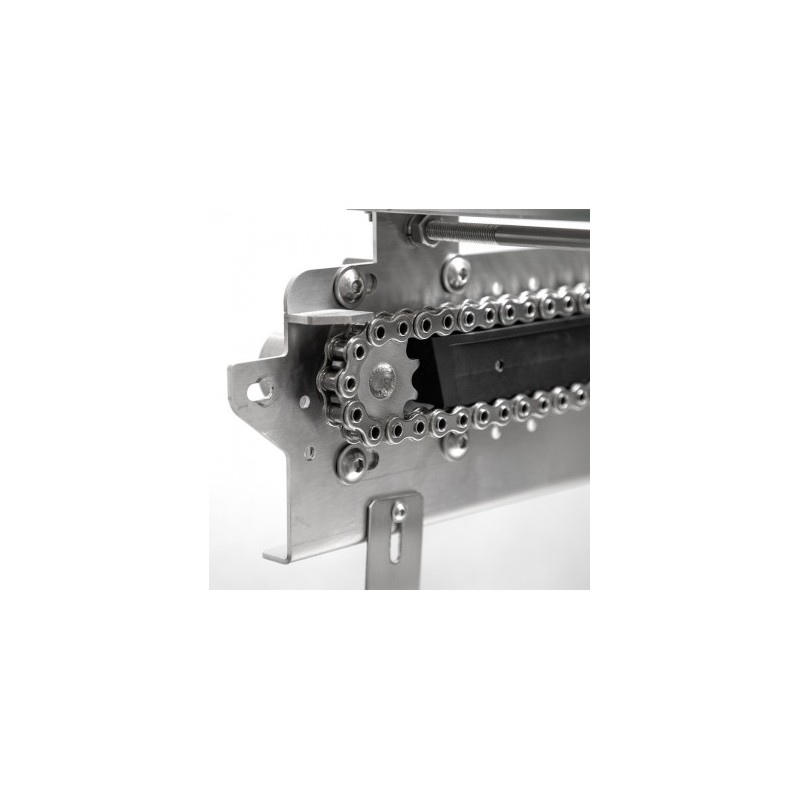

• Synchronized chain drive: precisely guides the frame under the knives, with adjustable speed.

• Digital control: manages temperature, speed, and machine status in real-time.

• Elevated chassis with collection tray: keeps the workspace clean and facilitates wax recovery for further processing (centrifuging, pressing, or melting).

Technical details you should know:

• Electrical supply: 220V three-phase (no 400V required)

• Material: high-quality stainless steel (PREMIUM line)

• Compatibility: Langstroth/Dadant US or Dadant Blatt version (select your format)

• Heated knives: temperature adjustable via digital panel

• Motorized chain: adjustable feed speed

• Includes: elevated stand and integrated collection tray

Practical recommendations:

• Ensure frames are at room temperature (25-30°C) for a clean cut.

• Adjust knife temperature based on the type of honey: sunflower or eucalyptus wax may need more heat.

• For large batches, combine with a wax cappings centrifuge to further streamline your workflow.

If your honey room needs more pace and less manual labor, this uncapper is an investment that makes a difference: less effort, more productivity, and a professional result.

Automatic uncapping machine with heated knives and electric feeder for Langstroth or Dadant frames. Designed for high-throughput professional honey houses.

check_circle

check_circle