- Pack

Instead of 1058 .00 €

Discover the wood-burning wax melter, an innovative and eco-friendly solution for melting and recycling wax from your hives. This system consists of two independent yet complementary components: the melter with a capacity for 15 frames and a wood burner. Ideal for beekeepers seeking a sustainable alternative to traditional heat sources like gas or electricity.

If you have been piling up old frames, comb scraps and broken wax sheets for years, a wood-fired wax melter like this one finally brings order to that winter job. Instead of melting wax in pots and improvised setups, you load the frames, light the fire and let the steam do the work, recovering kilos of clean wax in every batch.

The system works like a small steam generator. At the bottom you have the wood stove, above it the water chamber, and on top the compartment where you place the frames and comb pieces. The water heats up, produces steam and this rises into the upper compartment, melting the wax evenly. The liquid wax runs down into the tray and is ready to be poured into moulds to form clean wax blocks.

Correct use of the wood-fired stove

This is the critical point if you want the unit to last for many years without problems:

• The firebox must never be filled with more than one third of its volume in firewood.

• If you load more than that, the temperature rises too much, the metal expands excessively and some joints or sheets can come loose or deform.

• It is not an industrial melting furnace; it is designed to work with a moderate, steady and well controlled fire.

If you respect this loading limit, the melter runs at the right temperature, produces enough steam and the whole structure is under much less stress.

Firebox area: wear part and how to extend its life

As with any stove or boiler, the inner firebox chamber is a wear part. It is exposed to intense heat and, over the years, it is normal for it to deteriorate. The manufacturer considers it consumable and it is not covered by the warranty, just like on other combustion equipment.

Two simple tricks can greatly extend its service life:

• Line the inside with firebricks (chamotte). They distribute the heat better, stabilise the temperature and protect the steel from direct flame contact.

• If, over time, a joint loosens, you can reinforce or reseal the area with refractory cement or high-temperature silicone (the same type used for stoves and chimneys, resistant to around 1000–1500 °C).

With this basic maintenance, the firebox can handle many seasons without trouble.

Wax melter: capacity and working method

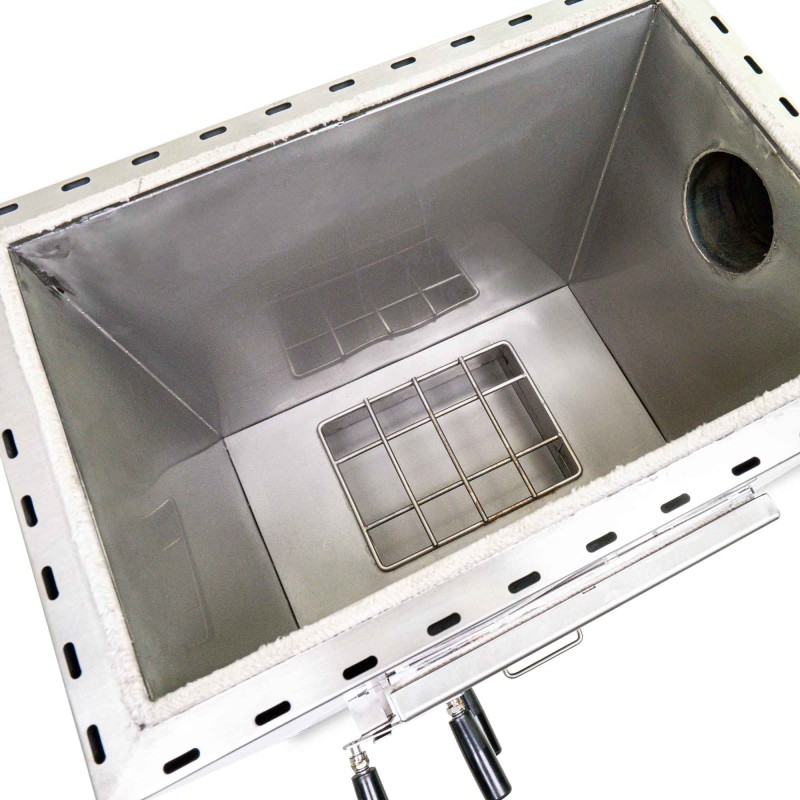

The wax melter is made of 1 mm thick stainless steel, with a square tank and integrated water reservoir. The upper compartment can hold approximately up to 15 Dadant frames, plus comb pieces and wax offcuts. This is a very convenient capacity for small and medium-sized operations that want to recycle all their wax without relying on gas or electricity.

In daily use, the workflow is simple:

• Fill the water chamber.

• Load the old frames and wax material into the top drawer.

• Load the firebox with a maximum of one third firewood and light it.

• The steam melts the wax without burning it, the impurities and residual honey stay at the bottom and you recover clean wax blocks, ready for the wax processor or for foundation making.

You also keep flexibility: the wax melter can be used with other heat sources, such as gas burners, and the wood stove can be connected to other compatible melters, as long as the dimensions match properly to avoid smoke leaks.

Dimensions and included parts

The melter has external dimensions of approximately 615 mm long x 415 mm wide x 850 mm high, with an internal working space of about 523 mm long x 320 mm wide x 495 mm high, designed for Dadant-type frames and wax blocks.

The wood stove measures roughly 48 cm high x 59 cm wide x 38.5 cm deep, with a total height of around 160 cm including the flue pipe and an overall width of about 75 cm.

The set includes:

• Square wax melter with water and wax compartments.

• Wood-fired stove with flue pipe.

• Wax collecting tray.

• Screws for the valves.

Used with a moderate fire, correctly loaded and with minimal maintenance (firebricks and sealant when needed), this is a unit that lets you melt a lot of wax every season in a simple, sustainable and very efficient way in your apiary or honey room.