Stainless steel wood-fired oven, fits BR-64404 wax melter. Perfect for melting wax off-grid—no gas or electricity needed.

Do you want to melt wax without relying on gas or mains power? This wood-fired burner lets you work fully off-grid, using simple firewood as your heat source. It is designed to fit perfectly under the BR-64404 wax melter, but it can also be used with other compatible melters that can make use of the heat generated by this stove. A robust, efficient and sustainable option to keep working all year round, even in rural areas or places with unstable electricity.

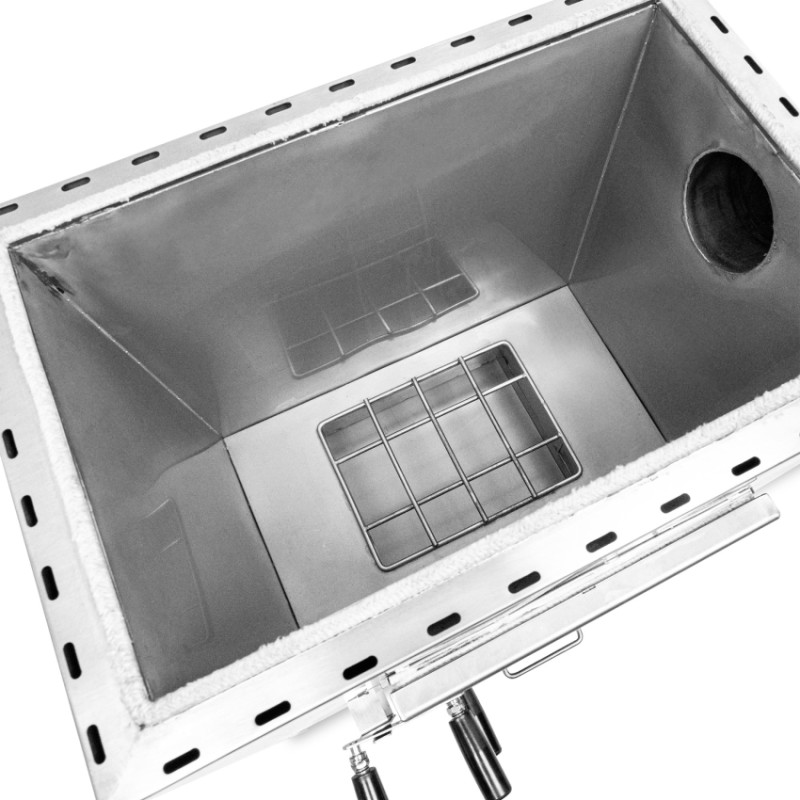

The body is made of stainless steel with a double insulated wall, which helps to distribute heat evenly and keep combustion stable. The flue and chimney are designed to work together with the melter, minimising smoke leaks and heat loss so you get the most out of every log.

Correct use of the wood burner

This is the key point if you want the stove to last for many seasons:

• The firebox must only be filled up to a maximum of one third of its volume with firewood.

• If you overload it, the temperature soars, the metal expands too much and sheets or welds may come loose (a typical symptom of overheating).

• It is not an industrial furnace; it is built to run with a moderate, steady and well-controlled fire.

If you respect this loading limit, the burner delivers plenty of heat and steam for the melter without putting unnecessary stress on the structure.

Firebox chamber: wear part and preventive maintenance

As with any stove or boiler, the inner firebox chamber is a wear part. Years of exposure to high temperatures will eventually fatigue the metal. The manufacturer therefore treats it as a consumable component, which is standard for combustion equipment and means it is not covered as a structural failure.

To maximise its service life, the following is recommended:

• Line the inside with firebricks (chamotte): they spread the heat more evenly, stabilise the temperature and shield the steel from direct flame contact.

• If over time a joint starts to loosen, you can reinforce or reseal the area with refractory cement or high-temperature stove silicone (sealants commonly used for stoves and chimneys, resistant to about 1000–1500 °C).

With this basic care and correct use, the burner will handle many wax-melting seasons without trouble.

Everyday feel

The feeling when you use it is simple: freedom. You can keep melting old frames and cappings without depending on gas bottles or power sockets, with a steady, controlled heat that helps preserve wax quality. It is not a makeshift setup; it is a tool designed to work hand-in-hand with your wax melter and to cope with the pace of a real harvest season.

Technical details:

• Stainless-steel body with double insulated wall

• Chimney/flue pipe included

• Height: 48 cm

• Width: 59 cm

• Depth: 38.5 cm

• Total height with chimney: 160 cm

• Width with chimney: 75 cm

⚠️ Important: Do not use in forest areas or within 100 m of woodland. Always follow local regulations on outdoor fire use and take extra care during high fire-risk periods.

A reliable solution for beekeepers who want full control over their wax-melting process, with autonomy, safety and no dependence on external energy sources.

Stainless steel wood-fired oven, fits BR-64404 wax melter. Perfect for melting wax off-grid—no gas or electricity needed.

check_circle

check_circle