Continuous operation without downtime. The Spinfloater SZ1350 separates honey and wax with precision through a Ø1,150 mm drum and automatic knife—maximizing honey recovery in professional honey-processing lines.

When the honey house is running at full capacity and cappings pile up by the bucket, every beekeeper wants the same thing: to recover as much honey as possible without dealing with cages, downtime or endless cleaning. The Spinfloater SZ1350 self-discharging cappings centrifuge is built precisely for that moment: it works continuously, separates efficiently and delivers clean honey on one side and wax ready for further processing on the other.

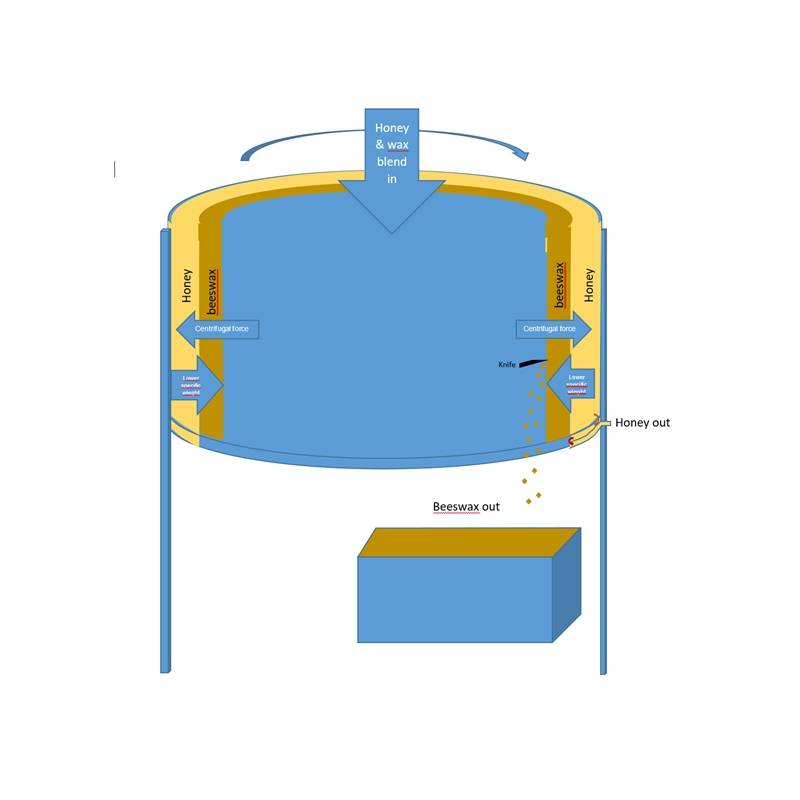

How it really works: feed the machine with a homogeneous mixture of honey and cappings at a stable temperature (ideally 38–42 °C). Inside the Ø1,150 mm drum, centrifugal force pushes the denser honey towards the wall, where it flows down by gravity to the base. The lighter wax floats inwards, forming a thin “crown” that a continuous cutting knife automatically peels off, discharging wax into a collection channel. The result is continuous wax discharge and clarified honey flow without overheating or interruptions.

Why it outperforms batch centrifuges: unlike the classic “cheese” type, you don’t need to stop to empty baskets or clean cages. The Spinfloater runs at a steady flow rate with continuous cutting, which means higher real throughput and less honey trapped in wax.

Pro tips that make all the difference:

• Keep the mixture between 38 and 42 °C (min. 35 °C, max. 45 °C). Colder honey = higher viscosity, poorer separation.

• Use a lobe or flexible impeller pump with frequency inverter for a smooth, pulse-free flow.

• Install a 3–5 mm coarse filter to remove debris or wire fragments and protect the pump and knife.

• The 3 kW bottom heater maintains temperature but does not heat cold product. Starting below 25 °C will cause clogging.

• For dense honeys (heather, oak) or high propolis content, slightly increase temperature or drum speed.

• At the end of each day, rinse knife and outlets with warm water – it will keep cutting cleanly for longer.

What most beekeepers overlook: separation depends not only on speed but on the balance between viscosity, density and flow. If the mix enters too cold or dry, wax clumps form and cannot be evacuated properly. Keeping a stable temperature throughout the process is key.

Professional recommendation: for a homogeneous feed, use a 3 m tubular heat exchanger (model 1.02), sold separately. It preheats the cappings mix gently before entering the centrifuge, preventing temperature spikes and clogs. It’s the simplest way to keep the SZ1350 working at its best.

What you’ll notice in the honey house:

• More honey recovered, less lost in wax.

• Continuous operation with no downtime.

• Easy cleaning and minimal maintenance.

• Stable honey without overheating or darkening.

Honest limitations: no machine can compensate for a poorly prepared feed. If the mix enters cold or uneven, separation efficiency drops. With a warm, homogeneous mix, a steady flow and basic cleaning after use, this centrifuge runs flawlessly all season long.

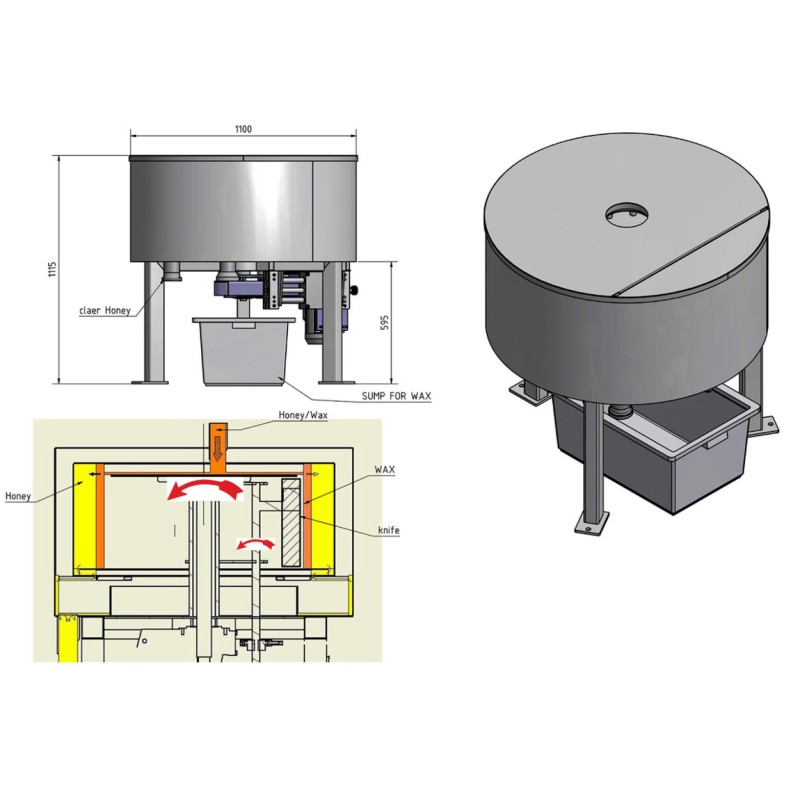

Key specifications – Spinfloater SZ1350: drum Ø1,150 mm • max. capacity up to 1,300 kg/h (depending on viscosity and temperature) • main motor 2.2 kW with gearbox • knife motor 0.55 kW • bottom heater 3 kW (230 V, 50 Hz) • variable speed control • continuous wax discharge • free honey drainage • stainless steel body with cleaning access • includes plastic wax tray • shipping pallet 125×125×150 cm, ≈400 kg.

Veteran’s summary: the SZ1350 separates by centrifugal force and density difference. Feed it warm, homogeneous and steady, and the knife will skim cleanly while honey flows pure. Perfect during rosemary or eucalyptus bloom, when every minute and every kilo count.