Developed in collaboration with experienced beekeepers and based on Ralf Kolbe’s original concept, this dual-function machine allows you to melt cappings wax and wash used frames simultaneously, saving valuable time and effort in the honey house.

After extraction, when you’re left with piles of sticky frames full of wax residues and propolis, you know the work isn’t over yet. This combined wax melter and frame washer turns that messy task into a clean, fast and efficient process: it melts and recovers wax without degrading it, while leaving the frames ready to go back into the brood box or super.

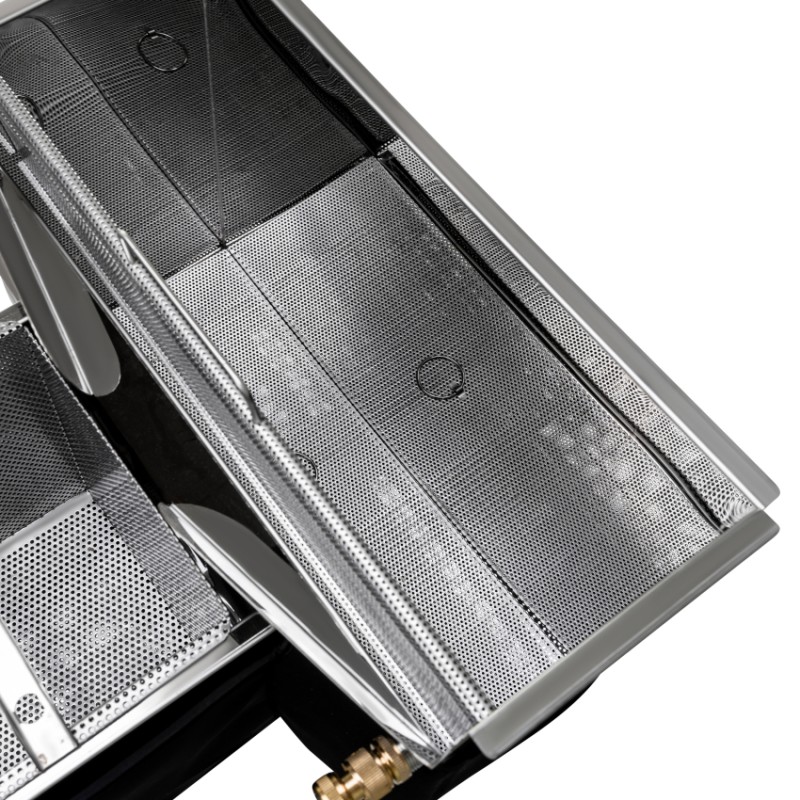

Made entirely of stainless steel, it features two independent tanks connected by a hydraulic circuit with a recirculation pump and hot water heating system. The water circulates continuously, maintaining an even temperature that loosens wax and propolis without damaging the wood. The insulated jacket minimizes heat loss and speeds up startup—something you’ll appreciate when the honey house is in full operation.

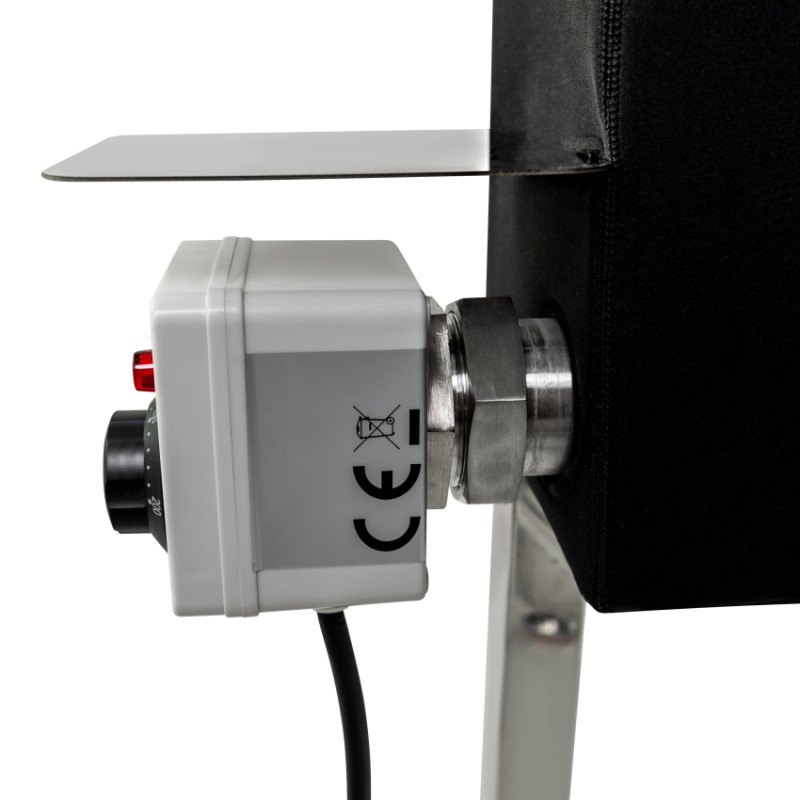

Operation is very practical: five stainless steel valves allow you to choose between recirculation, transfer or drainage; quick couplings and flexible hoses make assembly and cleaning easy; and the adjustable legs let you adapt the height to your working area. The removable thermostat provides precise temperature control to prevent overheating (keep below 90 °C to preserve wax color and aroma). The perforated basket retains cappings and debris, leaving the frames perfectly clean for reuse or storage.

Electrical connection and setup options:

This unit includes two independent 3 000 W heating elements (total 6 kW) and a recirculation pump of approx. 120 W. It can be configured for single-phase 230 V or three-phase 400 V operation depending on your electrical installation.

• In single-phase mode, it is possible to use only one heating element (3 kW) on a 230 V line with proper protection. The second element may be connected to another independent line if a separate fused socket is available. Both elements must not be connected to the same phase.

• For simultaneous use of both elements (6 kW), a three-phase connection with 5-pin plug (L1, L2, L3, N, PE) or a two-phase setup is recommended. Each element then operates on its own phase, achieving faster and more stable heating.

• The pump (~120 W) can be powered from the same line as one heating element.

Technical recommendation: always consult a qualified electrician to check cable section, protection, and phase balance, especially in regions prone to voltage fluctuations. Important: the unit is supplied without a three-phase plug, allowing it to be adapted to different protected configurations.

Workshop tips that work:

• Preheat the water with recirculation before loading the frames to save time and energy.

• Never run the pump dry (it reduces its lifespan). Make sure it’s primed before starting.

• For cappings heavily loaded after eucalyptus or sunflower blooms, extend recirculation slightly to improve impurity removal and frame cleaning.

Integrated technical specifications:

• Heating power: 2 × 3 000 W (screw-out elements for easy maintenance).

• Pump: ~120 W, always operate with liquid in circuit.

• Usable volume: approx. 73 L, ideal for continuous cycles in the honey house.

• Valves: 5 stainless steel ¾” valves for recirculation/transfer/drain control.

• Thermostat: immersion type, removable, for precise control.

• External dimensions: ~53 × 87 × 95 cm; weight: ~38 kg.

• Construction: full stainless steel body with thermal insulation and adjustable legs.

• Perforated baskets for debris and frames; quick couplings on hoses.

• Frame compatibility: Langstroth, Dadant Blatt and other standard formats.

In short: a robust and efficient unit designed for melting, cleaning and recovering wax with true professional quality. You’ll notice the difference when your frames come out spotless and your wax keeps its natural color and aroma.