Lyson Premium honey filling machine with integrated scale and gear pump, designed for beekeepers who fill large volumes of jars. It doses by weight with ±1 g accuracy, handles even dense honeys and can fill, pump and cream honey with a single unit, saving time and preventing you from giving product away.

If you are already filling hundreds of jars per season, you know the scene: you open the valve on the ripener, eyeball the level, close it, put the jar on the scale and you are over the target weight. You pour some honey back with a spoon, smear the lid and the label and, by the end of the day, the room is sticky and your back is complaining. That is the point where filling stops being beekeeping and becomes a repetitive manual job.

This Lyson Premium dosing machine is designed exactly for that stage of growth: when you can no longer afford to give away honey and hours of your time with an imprecise manual filling process.

The hidden cost of “giving honey away”

With manual filling we tend to overfill just to be safe with the legal net weight. If every jar is 10–15 g above target, on a 1,000 kg season you may be giving away around 30 kg of honey. That difference, year after year, is more than enough to pay for a precise and stable machine.

Integrated scale: constant weight, every jar

Unlike time-based fillers, which drift as soon as the temperature drops or the density of the honey changes, the Lyson W204006 has an integrated scale. You set the target weight and the machine doses until the scale reaches that value, automatically adjusting the working time of the pump.

In practice this means that:

• you can work, for example, at a constant 500 g without recalibrating when you change batch;

• the dose stays the same even if the honey is cooler or thicker;

• the typical error margin is around ±1 g, so you can stop overfilling out of fear of being short.

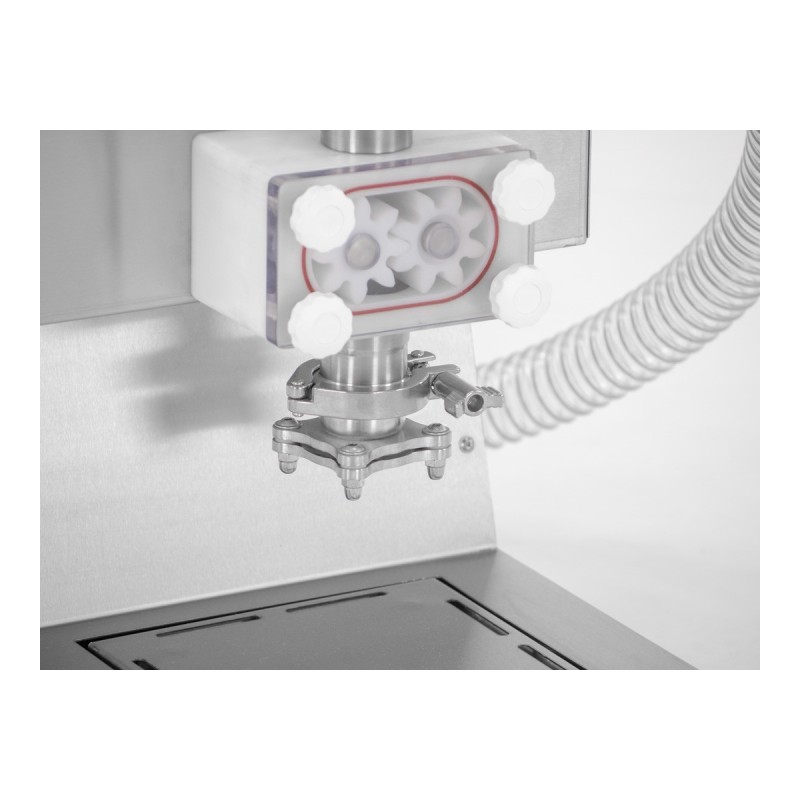

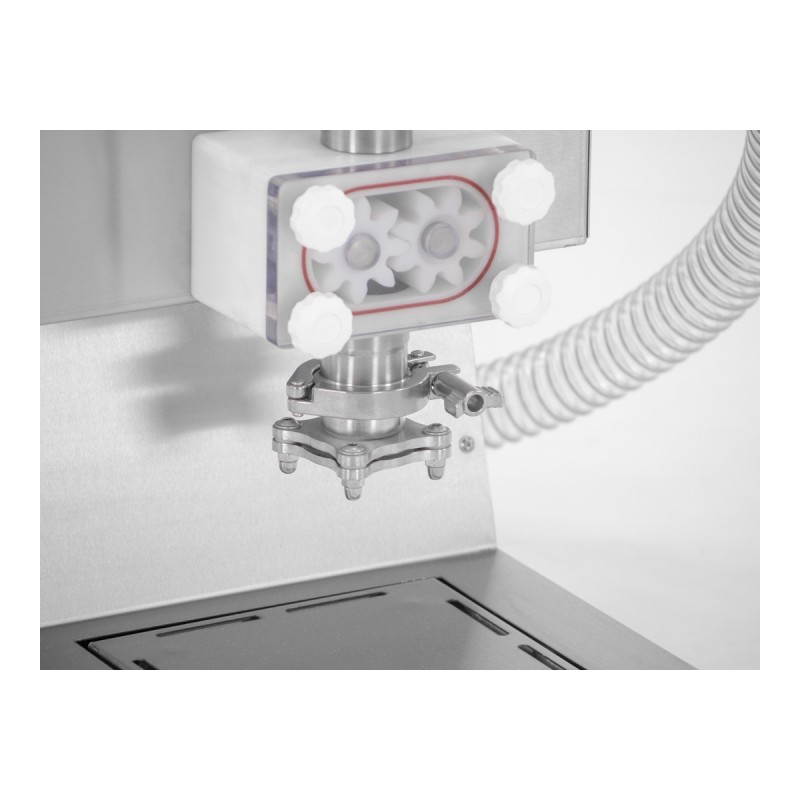

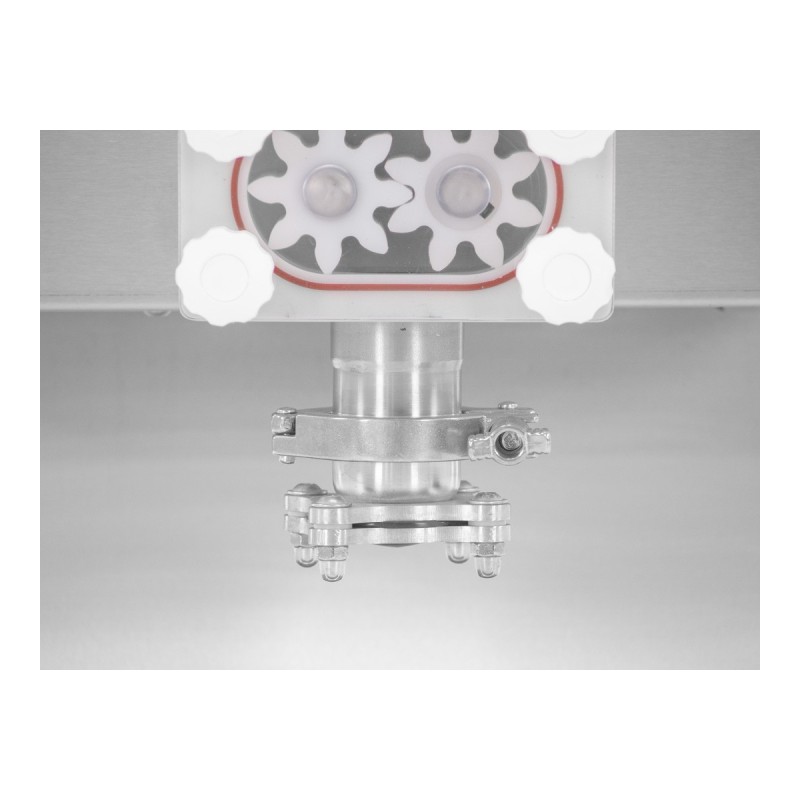

Gear pump: gentle and powerful for dense honeys

The heart of the unit is a high-precision gear pump. The gears move the honey in a continuous flow, without whipping in excess air. The result is a very stable stream, less foam at the top of the jar and a much cleaner filling process.

At the same time, the pump has enough torque to handle oak, forest or heather honeys without stressing the motor or losing output. It is a solution designed for honey rooms that work with very different viscosities throughout the year.

More than just a jar filler

The robust Mitsubishi touchscreen lets you select different working modes. In dosing mode you fill jars by weight; in pumping mode you can use the unit to transfer honey between ripeners; and in closed-loop mode you can take advantage of the circulation to help with creaming, breaking up larger crystals and moving towards that butter-like texture that gourmet customers love.

Details that make life easier in the honey room

The anti-drip system at the outlet keeps the working area cleaner. The bottom tray is removable, so if any drop of honey falls you just pull it out and wash it under the tap. The machine tares the empty container automatically before filling, so only the net weight of the honey is counted. With an organised workflow you can reach around 400 jars of 500 g per hour, finishing in a morning what used to take several shifts.

Technical specifications for professionals

The filling range goes from small samples of about 10 g up to containers of roughly 9 kg, covering everything from tastings to catering buckets. It runs on 230 V, so you can plug it into a standard outlet in a workshop or honey room without special electrical installation. The 180 W motor offers a good balance between power and low noise. It accepts jars with diameters of approximately 4 cm to 11 cm, covering most common glass and plastic formats. All parts in contact with honey are made of food-grade stainless steel and certified materials for food use.

Beekeeper’s advice

If you have already moved beyond a simple valve and kitchen scale, this Lyson Premium filling machine is a real step up. It professionalises your honey room, improves the presentation of your jars and, most importantly, stops you from giving away honey and working hours every season.

Lyson Premium honey filling machine with integrated scale and gear pump, designed for beekeepers who fill large volumes of jars. It doses by weight with ±1 g accuracy, handles even dense honeys and can fill, pump and cream honey with a single unit, saving time and preventing you from giving product away.

check_circle

check_circle