Industrial rotary wax melter with external steam boiler (3 × 1.5 kW). Efficiently melts old combs, wax scraps, and press residues without overheating. Processes up to 400 frames/day with temperature control and integrated cleaning system.

Anyone who has tried melting old combs with boiling water or solar melters knows how difficult it is to get clean wax without burning or wasting it. This rotary steam wax melter is designed for professional beekeepers who need a reliable, fast and energy-efficient system for wax recovery.

The unit consists of two parts: a mobile steam boiler and a rotating drum (Ø1000 mm). The boiler, equipped with three 1.5 kW heating elements (400 V 3-phase), heats about 25–30 litres of water to produce a steady flow of steam, which is fed into the drum through a flexible hose. Mounted on industrial castors, the boiler is easy to position near the melter.

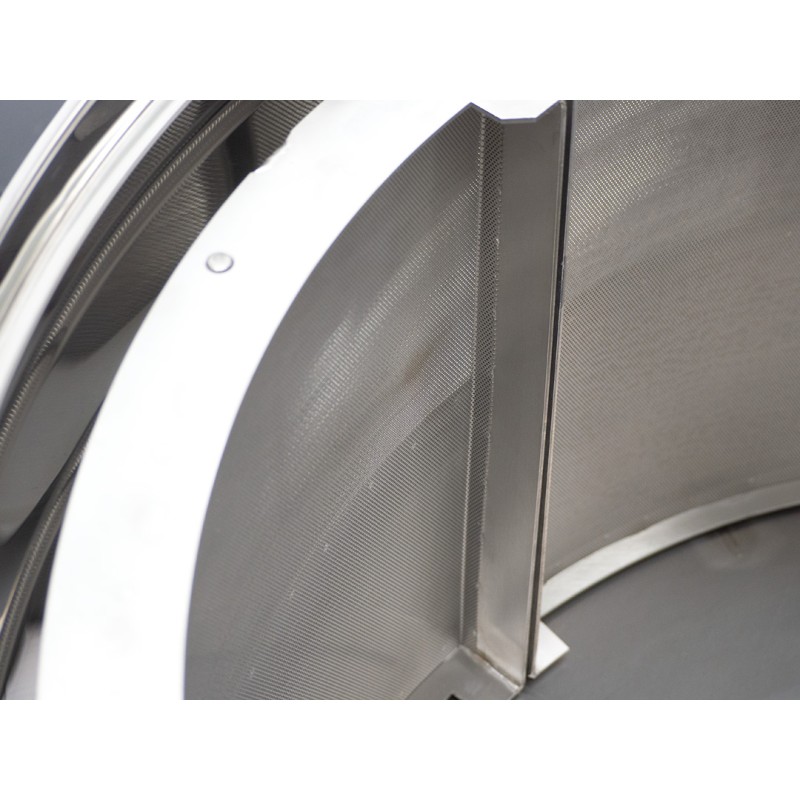

Inside the drum, steam circulates evenly and melts the wax indirectly – with no contact between wax and water. The slow, adjustable rotation of the drum ensures uniform heat distribution and efficient draining of liquid wax, which flows out through the bottom outlet and can be collected directly into a mould or container (not included). A stainless-steel mesh retains impurities such as cocoons, wires or wood pieces.

Each cycle takes around 20 minutes and allows the processing of 350–400 frames per day. The electronic controller (230 V) keeps the temperature stable at about 98 °C, preventing overheating and preserving the natural colour of the wax. Thermal insulation of the unit improves energy efficiency and ensures consistent results.

The melter can handle old combs, broken foundation sheets, dry cappings, pressed residues and recycled wax. It is not intended for fresh cappings containing honey, as the steam would dilute it. Wooden frames can be cleaned to remove wax residues, provided they are not wired.

For maintenance, the drum is equipped with two large cleaning nozzles connected to a water line for easy rinsing after each use. The boiler includes a drain valve and top access lid for refilling and cleaning.

Advantages compared to other systems:

• Indirect steam heating – no contact with water, cleaner wax.

• Rotating drum – faster and more uniform melting.

• Electronic control – constant temperature and safety.

• Mobile boiler – easy to move and position.

• Energy-efficient – lower consumption than boiling-water systems.

• Works year-round, unlike solar melters.

• Industrial-grade stainless steel construction for long life.

Technical specifications:

• Drum diameter: Ø1000 mm

• Heating power: 3 × 1.5 kW (400 V 3-phase)

• Controller: 230 V

• Working temperature: approx. 98 °C

• Cycle time: ~ 20 min

• Daily capacity: 350–400 frames

• Boiler capacity: 25–30 L water

• Rotation: adjustable speed motor

• Cleaning: 2 large water nozzles

• Material: thermally-insulated stainless steel

• Requirements: 400 V 3-phase, 230 V and water supply

This machine combines the power of steam with the precision of controlled rotation, delivering clean, pure wax with minimal labour. Perfect for professional beekeeping facilities and wax-recycling operations.